Procédé de fabrication

Les matières plastiques que nous transformons se présentent sous la forme de granulés.

Avant d’être utilisées, certaines d’entre elles, absorbant l’humidité ambiante, doivent être séchées dans des étuves où circule de l’air chaud et sec pendant un temps défini.Les matières sont ensuite chargées dans la trémie de l’extrudeuse, puis entrainées par une vis sans fin à l’intérieur d’un cylindre chauffé à une température dépendant de la nature de la matière.

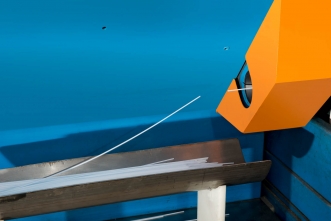

La matière fondue est alors poussée à travers une filière à la forme du produit recherché.Le tube ou le profilé doivent alors être refroidis et passent donc à travers un équipement spécial, le conformateur, dont le but est de refroidir le produit en lui donnant ses cotes finales définitives.

Le produit extrudé est ensuite entrainé, mesuré en continu par laser, puis coupé à longueur , ou conditionné en bobines ou couronnes.