Co-extrusion plastique

La coextrusion plastique consiste à extruder deux matières différentes pour réaliser un même tube ou un même profilé.

Chaque matière apporte ses propriétés propres au produit final.

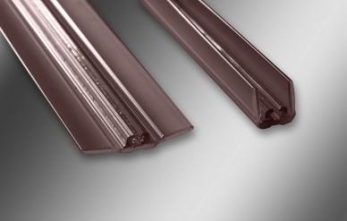

La coextrusion la plus fréquente consiste à extruder une partie rigide pour la structure avec une partie souple pour l'étanchéité.

On peut également coextruder deux couleurs différentes ou bien une matière technique et une matière économique.

Pour obtenir un tube ou un profilé coextrudé, deux extrudeuses sont accouplées, chacune extrudant une matière, un outillage commun fixé sur la sortie de chaque machine permettant aux deux matières différentes de se rejoindre et se souder pour ne plus former qu’un seul tube ou profilé.