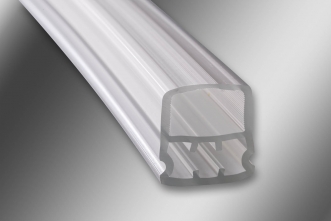

Profilés plastiques souples

Les profilés souples sont souvent utilisés pour répondre à des contraintes d’étanchéité , d’amortissement de choc ou de bruit.

Les matières utilisées sont définies par leur dureté Shore A comprise entre 30 Sh.A et 90 Sh.A pour les plus fréquentes.

Chacune possède des caractéristiques propres telles que résistance à l’abrasion, à la compression, dureté, transparence et aptitude à la coloration, résistance aux UV. Dans la plupart des cas, les matières souples ne peuvent être utilisées pour des températures supérieures à 80 °c.

Les profilés souples peuvent être conditionnés en couronnes, sur bobine ou coupés à longueur. Le mode de conditionnement devra être défini de façon à éviter le risque de déformation du produit postérieur à l’extrusion plastique.

La coupe à longueur en ligne est souvent délicate car le profilé aura tendance à se rétracter en refroidissant. En cas de tolérance serrée sur la longueur une opération de reprise pourra être nécessaire, une fois le profilé stabilisé.

Exemples d'application

Automobile

- Profilés d’étancheité et usure pour planchers

- Profilés pour toits ouvrants

- Profilés antichocs divers

Sport

- Profilés pour roues de vélos

Textiles

- Divers profilés de finition pour uniformes

Matières transformées

PVC, PEBD, TPU , TPV, EVA , PEBA , TPV, TPEE, SEBS…